As organizations identify these KPIs, it also needs periodic review. This step is where companies identify crucial performance metrics. This way, roadblocks are identified and managed before a problem crops up. For this reason, it is essential to take stock of everything integral in the order fulfillment process. This lean management framework operates on a small margin of error.

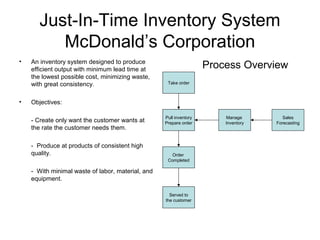

The first step in the JIT inventory management process involves reviewing all the key players that constitute the supply chain. Reviewing the Manufacturing Building Blocks.However, below are the processes that most retailers do when they utilize practice this lean management strategy: That said, the JIT inventory management cycle can come in many forms. “Pull triggers” determine when a new shipment is due to be shipped from the supplier or manufacturer. The JIT process involves sourcing inventory or raw materials when an order comes in or when demand for a product is forecasted. As an example of that, early adopter Toyota, took 15 years to perfect their process. One of the goals of the JIT framework is to improve itself continually. Automobile manufacturer Toyota originally developed JIT inventory management. It was developed in post-war Japan in the 1970s to solve the imbalance between the scarcity of resources, space, and cash and the increasing demands for consumer products. Because they do not hold safety stock, they invest in accurate demand forecasting for their products. It is a lean management framework that involves ordering and receiving the merchandise for order fulfillment only as needed.īusinesses that operate on a JIT inventory management strategy do not often carry plenty of products in stock. Just-in-Time inventory management, or JIT, is a type of inventory management strategy that aims to reach maximum efficiency while lowering costs. For many businesses, online or otherwise, shifting to a Just-in-Time inventory management system improved their supply chain and reduced inventory management costs. Too much inventory in stock can affect your bottom line likewise, light inventory levels can affect order fulfillment time.

That’s why it’s essential to find the balance between overstocking and understocking requires a level of finesse. While these numbers are good for the global economy, it does pose several challenges, one of which is inventory management. More than 3 billion packages got delivered during the 2020 holidays, and billions of people made online transactions for several years.

0 kommentar(er)

0 kommentar(er)